material flow analysis

material flow analysis

A prerequisite for transport systems to be planned and implemented in a manufacturing plant is to know what actual transport capacity is currently needed and will be needed in the long run.

The transport of work in progress is seldom a matter of going from A to B moreover it is a complex system of production stations that are visited during the production process.

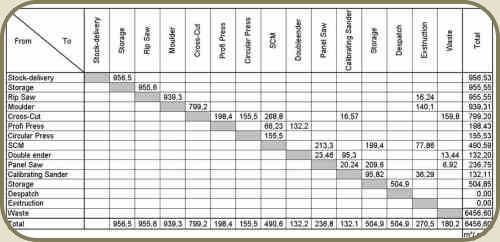

To get a good overview of the transportation capacity needed it is recommended to create a matrix, in which all products that need transport and the distance these components have to be transported, are accounted for.

Not only can the requirements be identified, the transport matrix is also a great tool to verify the current layout of a production plant. Ultimately the complete flow of material can be optimised.

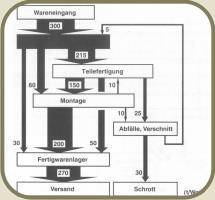

The material flow is identified schematically:

- defining the product spectrum to be analysed,

- defining the transport unit,

- defining time unit,

- illustrating the material flow,

- conclusion.

Analogue to the material flow the distance matrix is created. Here the distance of all stops during a production process is accounted for.

The combination of these diagrams show the needed transport capacity.